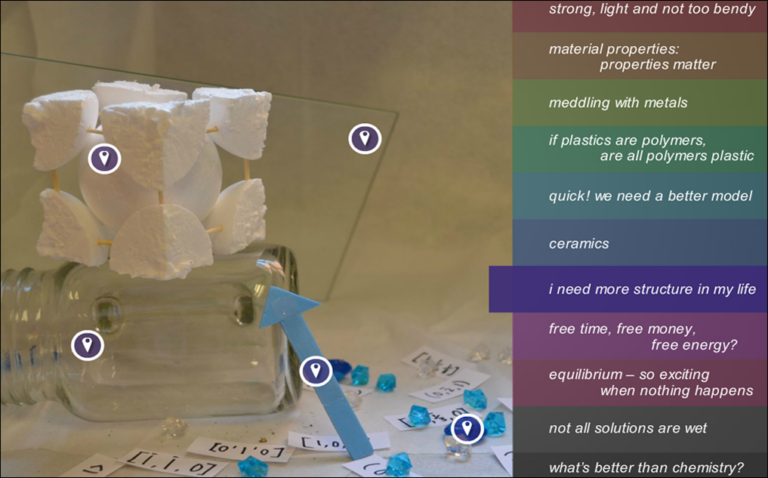

Meddling with matter

Learning Outcomes

- Identify on the stress-strain curve for a typical metal the following points or regions: proportional limit, yield strength, ultimate tensile strength, fracture strength, linear elastic region, non-linear elastic region, uniform elastic deformation, uniform plastic deformation, non-uniform plastic deformation, onset of necking, ductility, toughness, and modulus of resilience

- Compute the true stress and true strain

- Compare and contrast the engineering stress and strain with the true stress and strain

- Derive equations for the true stress and true strain based on the assumption of constant volume

- Demonstrate how plastic deformation in metals occurs through the movement of linear crystalline defects

- Organize crystalline defects according to their dimensionality, that is, zero-dimensional, one-dimensional, two-dimensional, and three-dimensional

- Summarize the four major strengthening mechanisms in metals

Related Project Resources

| Type | Title | Author | Description |

|---|---|---|---|

| File | Meddling With Matter (SCORM Package) (ZIP, 3.3 MB) | Prof. Scott Ramsay | |

| File | Meddling with matter (Storyline File) (ZIP, 97 MB) | Prof. Scott Ramsay | |

| Video | Mechanical Behaviour of Metals | Prof. Scott Ramsay | Basic overview of the generalized stress-strain behaviour of a typical metal in tension with a brief introduction to the 0.2% offset yield strength. (Duration: 09:48) |

| Video | The stress-strain behaviour of metals | Prof. Scott Ramsay | In this video I discuss the general stress-strain behaviour of metals and define the yield strength, ultimate tensile strength, and fracture strength. (Duration: 08:43) |

| Video | Uniform and non-uniform deformation in metals | Prof. Scott Ramsay | Quick look at unifrom and non-uniform deformation (necking) in metals. (Duration: 03:38) |

| Video | Strain hardening in Metals: True stress and true strain and the Holloman equation | Prof. Scott Ramsay | In this video I introduce true stress and true strain which then allows us to use the strain hardening equation. (Duration: 08:19) |

| Video | Ductility, toughness and resilience | Prof. Scott Ramsay | (Duration: 11:03) |

| Video | Mechanism for permanent deformation in metals | Prof. Scott Ramsay | This video is about Mechanism for plastic deformation in metals. (Duration: 12:20) |

| Video | Imperfections in solids: 0-Dimensional (Point defects) | Prof. Scott Ramsay | This video is about Zero dimensional or point defects and solid solution strengthening. (Duration: 11:56) |

| Video | Imperfections in solids: 1-Dimensional (Linear defects) | Prof. Scott Ramsay | This video is about One dimensional or linear defects and Strain hardening. (Duration: 09:25) |

| Video | Imperfections in solids: 2-Dimensional (Interfactial defects) | Prof. Scott Ramsay | This video is about Area defects and strengthening by grain size reduction. (Duration: 11:22) |

| Video | Imperfections in solids: 3-Dimensional (Volume defects) | Prof. Scott Ramsay | This video is about Volume defects and precipitation hardening. (Duration: 06:02) |